ERTEK control warehouse environment with W-Modbus, Modbus RTU through reliable wireless mesh

Building automation expert ERTEK has chosen LumenRadio’s wireless Modbus solution, W-Modbus, to control warehouse environments in Morgongåva Business Park, reducing installation cost and increasing flexibility.

ERTEK, a Swedish building automation expert, supports their customers throughout the whole building process, from the design of the solution, through commissioning and later support for the building.

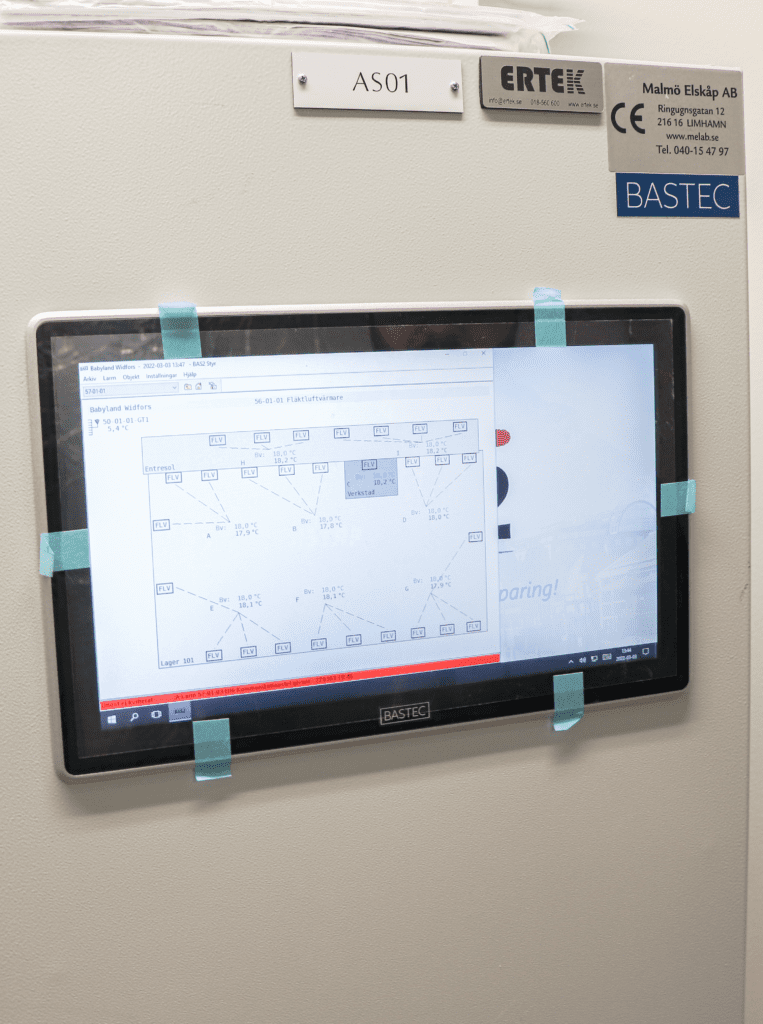

Morgongåva Business Park, located 40km north of Uppsala in Sweden, hosts several e-commerce warehouses such as Apotea, Babyland, Widforss, Delitea, Happy Yachting, Smarta saker and Adlibris – companies depending on optimal temperature and environmental conditions for their products.

ERTEK won the project to deliver all the building automation and support for Morgongåva Business Park and quickly they realized that using wires to connect all the wall-heaters, sensors, controllers, and roof fans was not an option since this would be too costly.

Instead, ERTEK chose to use wireless sensors that connect to a gateway and LumenRadio’s W-Modbus devices. The W-Modbus solution replaces the signaling cable and instead you get Modbus RTU network through reliable wireless mesh technology.

The meshing technology in the W-Modbus product made the installation easy even though there were large areas that needed to be covered – the network performed exceptionally. The wireless technology increases the flexibility of the installation and retrofitting extra functionality to the building automation system was easy.

Temperature control at its best

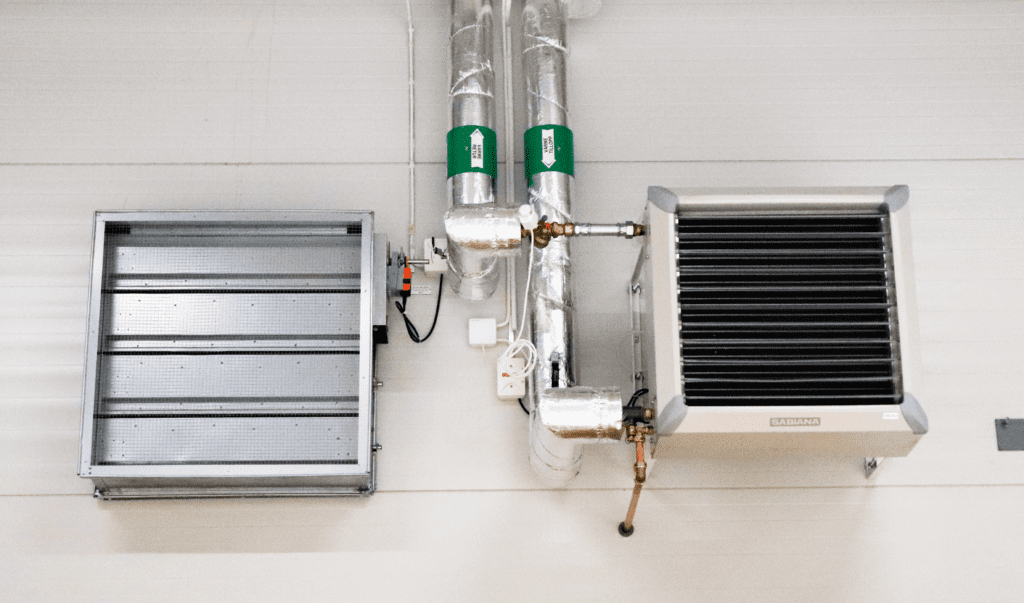

To control the environment in the warehouse temperature values are collected and compared to setpoints. If the setpoint is higher than the temperature the wall heaters are started and if the temperature is higher than the set point the wall ventilation is opened.

The temperature difference is also measured between the roof temperature and the ground temperature in the warehouse and if there is a temperature difference the roof fans are started to circulate the air in the warehouse.

All the sensor values are collected to a gateway that in turn is connected over the W-Modbus network to the controller. All the setpoints are also being collected and updated over the W-Modbus network.

Cost savings

Simon Karim is a project manager at ERTEK and explains that the major benefits with W-Modbus for them are:

- The wireless equipment costs less than a wired solution.

- Installation of a wireless system is significantly quicker than a wired solution.

- Cables are often not accepted in projects, due to aesthetics, in for example churches or museums.

“But it is the decrease of the installation time that is the absolute biggest cost saving. To be able to test and validate the plant before commissioning, is a big win” says Simon and concludes:

“With W-Modbus we were able to decrease the installation cost compared to a wired installation and at the same time create a flexible system where it was easy to add units when changing the layout, we are very satisfied with the result.”